CAD & CAM Services

CAD & CAM Designing Services:

Excellence in Fabrication, Welding, and Machining Services

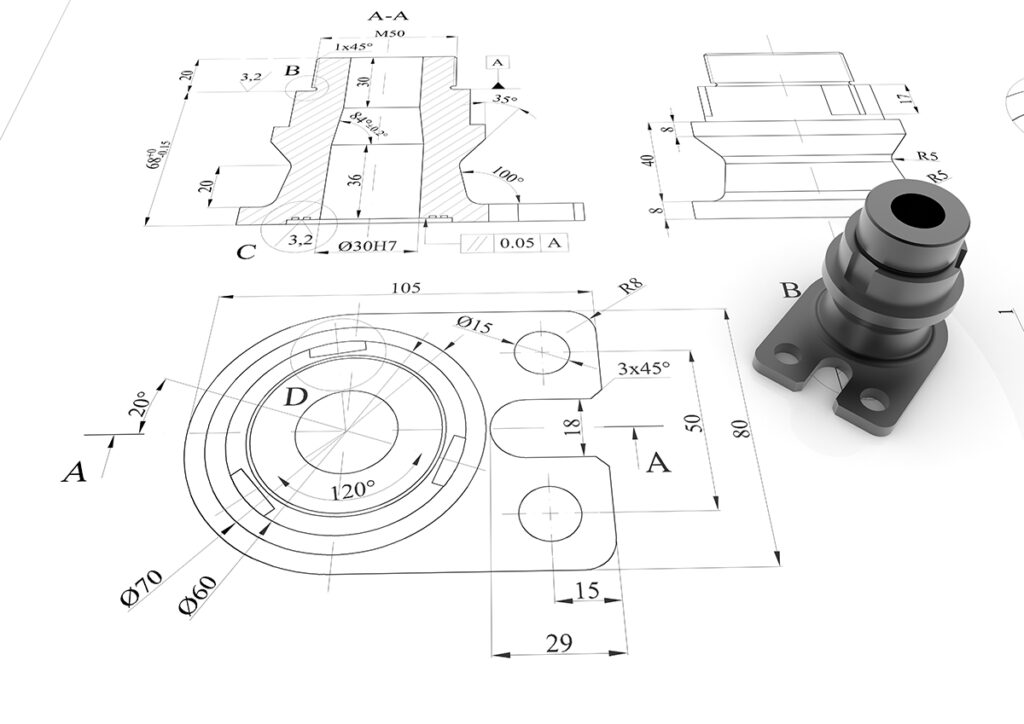

Drawing to 2D Drafting

1. Utilizing CAD software for precise creation of drawings and technical illustrations

2. Accurate dimensioning, annotations, & detailing for clear design communication

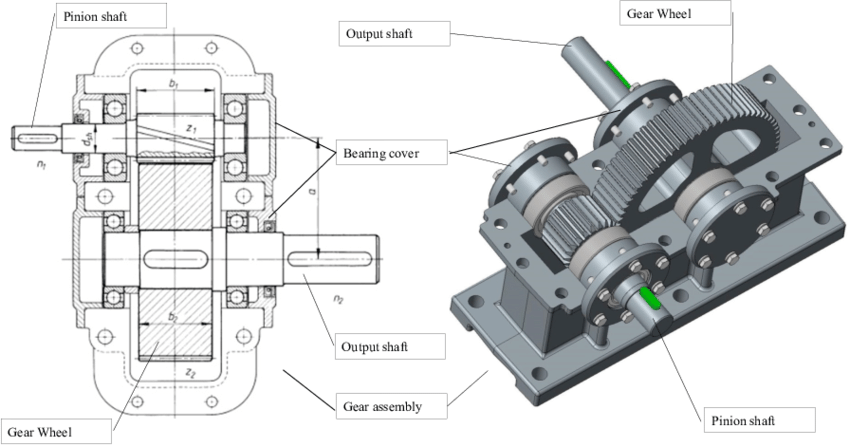

2D to 3D

Modelling

1. Transforming 2D sketches and designs into immersive and realistic 3D models

2. Visualization of components and assemblies from multiple perspectives

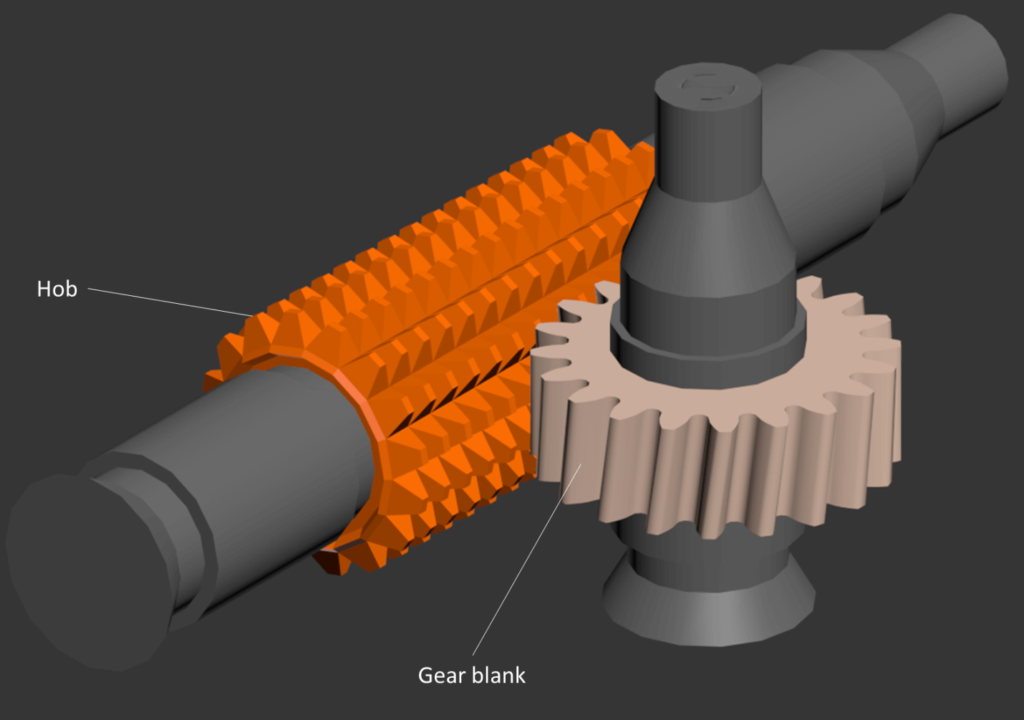

CNC Programming Solutions

1. Generating CNC programs from 2D and 3D models for precision machining

2. Optimizing toolpaths to maximize efficiency and minimize production time

Animated Models

1. Utilizing CAD software for precise creation of drawings and technical illustrations

2. Accurate dimensioning, annotations, & detailing for clear design communication

Structural & Machining

Excellence in Fabrication, Welding, and Machining Services

Structural fabrication is a fundamental process in the construction industry that involves the manufacturing and assembly of components used to create buildings, bridges, and other structures. It encompasses a range of activities, including cutting, bending, welding, and assembling various materials such as steel, concrete, and aluminum. The goal of structural fabrication is to produce high-quality, durable, and safe structures that meet design specifications and withstand the test of time. Skilled fabricators and technicians utilize advanced technology and equipment to ensure precision and efficiency throughout the fabrication process. Quality control measures are implemented to guarantee compliance with industry standards and regulations, ensuring that the final product meets the highest standards of safety and performance. Structural fabrication plays a critical role in shaping our built environment and is essential for creating solid foundations that support and connect communities.

Machining is a precise and versatile manufacturing process that involves the shaping, cutting, and refining of materials to create precise components. It is a key technique used in various industries, including automotive, aerospace, electronics, and medical. Machining utilizes a range of tools such as lathes, milling machines, drills, and grinders to remove material from a workpiece and achieve the desired shape and dimensions. With the aid of computer numerical control (CNC) technology, machining has become even more efficient and accurate, allowing for complex geometries and intricate designs. Skilled machinists operate the machines and follow precise instructions to ensure the highest level of precision and quality. The process involves careful selection of cutting tools, appropriate speeds and feeds, and meticulous measurement and inspection to meet tight tolerances and specifications. Machining plays a crucial role in the production of components with exceptional accuracy and surface finish, enabling the assembly of intricate machinery and products.